|

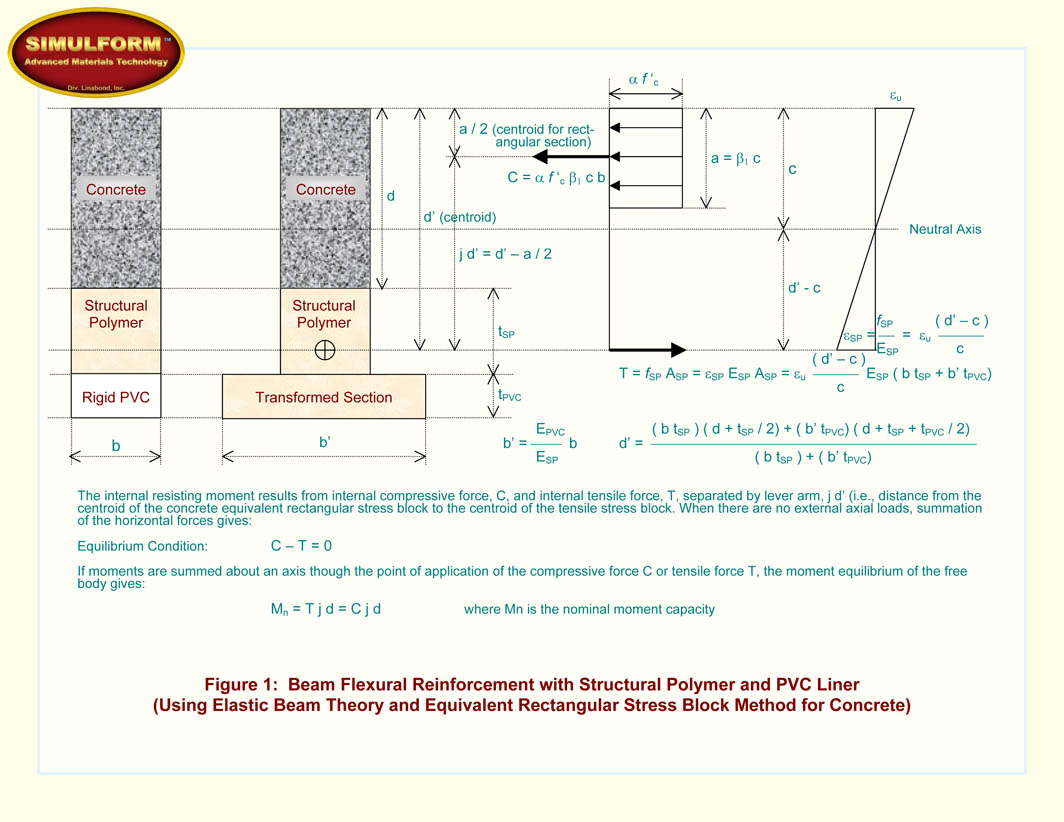

Above, you can see part of the theory behind Simulform Structural Reinforcement. You can open this page by clicking on it to open a one-page PDF file. Below, is the reality. |

|

||

Above, the structural reinforcement capabilities of a Simulform® Co-Liner™, tells the real story on how well thes Co-Liners perform. This test can be repeated with the SAME Simulform® Structural Reinforcement hundreds or even thousands of times - with the same results. With Simulform® Structural Reinforcement , the concrete flexes and withstands nearly 8,000 pounds, and returns to its original form - time, after time, after time. More than 10 times the enhancement provided by a high-strength Polymer Grout material of the same thickness. STEEL reinforcement, cannot do this, nor can anything else! |

||

Should we expect anything less from those who design our workplaces, homes, cities, power plants and industrial infrastructure? |

|

Simulform uses a wide variety of materials for structural reinforcement, tailored to accommodate the need for typical “movement” in our buildings, containers, Power Plants, storage facilities, and much more. Power Plant reinforcement has become an increasingly troublesome problem, just as our dams and offshore drilling structures have become a serious structural reinforcement problem. Many of our housing and commercial developments are in dire need of building reinforcement. In the event of common natural disasters and phenomenon, our building reinforcement, container reinforcement and power plant reinforcement should be designed to accommodate a “worst-case scenario”, rather than a “best-case scenario”. We should not be caught using an “umbrella” in a hurricane. It simply doesn't make sense to ignore the vagaries of our natural environment, and the needs of our increasingly larger cities and civilization. Our Structural Reinforcement, should evolve to accommodate our increasing levels of centralization, and our needs for food, protection, transportation, water, and power, worldwide. Does it make any sense to you, that our automobiles and aircraft undergo “crash testing” and are thereby made much safer and more durable than our Building Reinforcement, Container Reinforcement and Power Plant Reinforcement? Are we really using the best materials and designs for earthquake protection, and protection from hurricanes, floods, fires and tornadoes? Compared to our automobiles, our cities, buildings, industrial infrastructure and housing are woefully antiquated in their design and construction. That simply should not be the case, when the materials and technology are readily available and relatively inexpensive. Structural reinforcement with modern materials and design, should not have lagged so far behind our automotive materials and design, but it has. We have, far too often, become the victims of our own technologies, rather than the benefactors. It is a trend that we must reverse, if we are to move civilization forward sensibly. The technology for Structural Reinforcement, is THERE. You can see it, and it works exceedingly well. It has proven itself as Structural Reinforcement over decades of use in Public Works. |

Simulform® Material Systems

- Advanced Composite Structural Reinforcement

- Tank and Containder Protection and Rehabilitation

- Superior Roofing Systems

- Decking Support, Sub-Membranes and Waterproofing

- Earthquake and Blast Protection for New and Retrofit Construction

- Designed for both new construction and rehabilitation of existing structures.

Simulform® Construction is similar in many ways to "protection" that is common in Military, Law Enforcement and Disease Control. Law enforcement officers do not go into a "hazardous environment" without a real "flack jacket and armor". They do not apply a coating to their bodies, or carry around steel-reinforced concrete plates, and hope that it will protect them from harm - nor do they use simple concrete and steel construction for armor and blastproofing. They typically wear a laminar composite with... backup protection. And they use nearly indestructible armor.

|